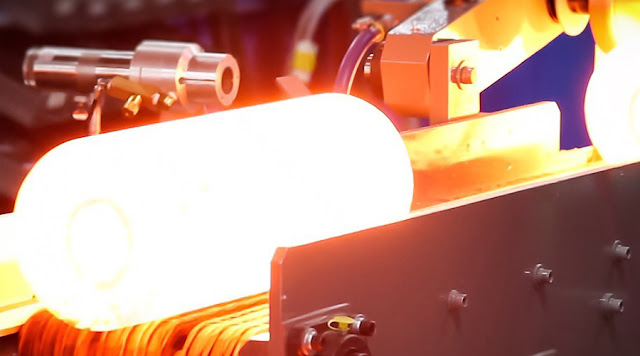

Billet Induction Melting Furnace

The billet induction melting furnace is an important equipment in the metal casting industry. It plays a vital role in the melting and refining of the metal industry, ensuring the production of high-quality steel billets that can be further processed into a variety of products. In this article HANI METALLURGY will discuss with you the working principles, advantages and applications of billet induction melting furnaces.

How an induction melting furnaces works: revolves around the concept of electromagnetic induction. It consists of a lined refractory crucible used as a furnace and an induction coil that generates a high-frequency electromagnetic field. When alternating current passes through a coil, it creates a magnetic field around the coil.

This magnetic field induces an electric current in the conductive blank, causing it to rapidly heat up and melt.

Advantages of billet induction melting furnace

One of the significant advantages of using a billet induction furnace is its efficiency.

The use of induction heating ensures rapid and even heating of the blank, resulting in shorter melting times compared to traditional methods. Additionally, precise control of temperature and power input allows for precise and consistent melting of metal, minimizing the risk of overheating or underheating. This level of control also helps produce alloys with specific compositions and properties.

Another advantage of billet induction furnaces is their safety features. Unlike other melting methods that require direct contact with a flame or hot surface, induction heating furnaces do not involve any open flames or exposed heating elements.

This eliminates the risk of accidents such as burns or fire, making it a safer option for operators. In addition, there is no combustion gas and smoke, reducing environmental pollution and creating a cleaner and healthier working environment.

The versatility of induction melting furnaces is another noteworthy aspect. It can melt a variety of metals, including steel, aluminum, copper and other non-ferrous alloys.

This flexibility makes it a valuable asset in various industries including automotive, aerospace, construction and manufacturing. Whether casting billets, ingots or other semi-finished products, the furnace can handle metals of different sizes and shapes.

In terms of operating costs, induction furnaces can provide significant cost savings. Its energy efficiency combined with precise temperature control reduces power consumption. Fast melting times and consistent heating also minimize material waste, increasing productivity and reducing material costs. Additionally, the furnace's rugged design and durability help reduce maintenance and repair costs, making it a cost-effective investment in the long run.

In conclusion, the billet induction melting furnace is an indispensable tool for the metal casting industry. Its efficient and precise heating capabilities, combined with safety features and versatility, make it ideal for melting and refining a variety of metals.

The furnace is capable of producing high-quality steel billets and plays a vital role in the manufacturing of various products. As technology continues to advance, billet induction melting furnaces will undoubtedly continue to evolve, further improving their efficiency and capabilities.

If you have any questions about induction furnaces, electric arc furnaces, ladle furnaces, refining furnaces and other metal smelting furnaces, you can contact us.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment