20-50KG DC Submerged Arc Furnace

20-50KG DC submerged arc furnace: a powerful smelting furnace in the metallurgical industry.

In the field of metallurgy, the development of advanced technology and equipment has greatly promoted growth and innovation in various industries.

One of the significant advancements is the 20-50KG submersible furnace. This specialized furnace plays a vital role in the production of high-quality metals and alloys, making it an indispensable tool for many metallurgical applications.

Overview of DC Submerged Arc Furnace:

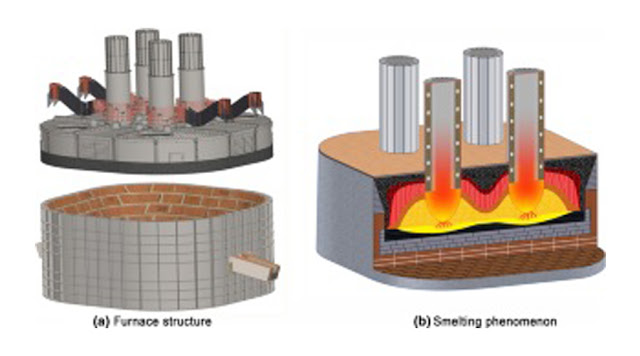

The DC SAF is an electric furnace that uses direct current as the power source for the smelting process. It consists of a cylindrical refractory lined vessel (often called the furnace shell) immersed in a conductive slag bath. The furnace is filled with a mixture of raw materials, usually a combination of metal oxides and a carbon-based reducing agent.

Working Principle of Submerged Arc Furnaces:

The operation of the 20-50KG DC submersible furnace is based on the arc principle. A pair of graphite electrodes are placed vertically in the furnace shell, with their tips immersed in a conductive slag bath. When current passes through the electrodes, an arc forms between them, generating intense heat.

The heat generated by the arc melts the raw materials inside the furnace, causing various chemical reactions. A carbon-based reducing agent, such as coke or anthracite, reacts with the metal oxide to reduce it to its metallic form. The molten metal then collects at the bottom of the furnace, while impurities are trapped in a slag pool.

Applications of Submerged Arc Furnace:

20-50KG DC submerged arc furnace is widely used in ferroalloy production. Ferroalloys are important components in the steelmaking process, improving the mechanical and chemical properties of the final product. Commonly used ferroalloys include ferromanganese, ferrosilicon and ferrochromium.

Ferromanganese: This alloy is used to increase the strength and hardness of steel, making it suitable for a variety of industrial applications. Submerged arc furnaces facilitate the efficient production of high-quality ferromanganese by precisely controlling the temperature and chemical composition of the smelting process.

Ferrosilicon: Ferrosilicon is widely used as a deoxidizer and alloying agent in stainless steel production. Its addition helps improve the corrosion and heat resistance of the final product.

DC SAF ensures precise control of silicon content in ferrosilicon, enabling the production of alloys with consistent properties.

Ferrochromium: Ferrochromium is an important component in the production of stainless steel and has anti-corrosion and anti-oxidation properties.

Submerged arc furnaces can smelt ferrochromium efficiently, ensuring precise control of chromium content to meet specific industry requirements.

Advantages of Submerged Arc Furnaces:

1. Energy efficiency:

The metal smelting furnace uses DC power supply and has high operating power efficiency. This reduces energy consumption and lowers operating costs.

2. Precise temperature control:

DC power supply enables precise temperature control to ensure optimal conditions for the smelting and alloying process. This precision helps produce high-quality metals and alloys.

3. Versatility:

The furnace can accommodate a variety of raw materials and can flexibly produce different alloys. Smelting furnaces are capable of processing different raw materials and are therefore suitable for a variety of metallurgical applications.

4. Reduce environmental impact:

Submerged arc furnaces operate in a closed system, minimizing the release of harmful emissions into the atmosphere. In addition, efficient combustion and heat transfer systems help reduce greenhouse gas emissions.

5. Increase productivity:

The advanced design and control system of DC submersible furnaces can achieve continuous operation, thereby increasing productivity and output. The furnace is capable of efficiently processing small-scale batches, which is particularly advantageous for research and development purposes.

The 20-50KG DC submerged arc furnace is a powerful tool that plays a decisive role in the metallurgical steel industry. Thanks to precise temperature control and energy efficiency, its able to efficiently produce high-quality ferroalloys, making it an indispensable asset in a variety of applications.

As demand for advanced alloys continues to grow, DC and AC submersible arc furnaces will continue to play a vital role in shaping the future of metallurgical advancement and industrial development.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment