Automation of Metallurgical Industry - EAF

Automation of metallurgical industry, particularly the electric arc furnace (EAF) process, has revolutionized the way steel is produced. With the advancement of technology, automation has become a key factor in improving efficiency, reducing costs and improving safety in the metallurgical industry. In this article, we will explore the automation of the EAF process and its benefits.

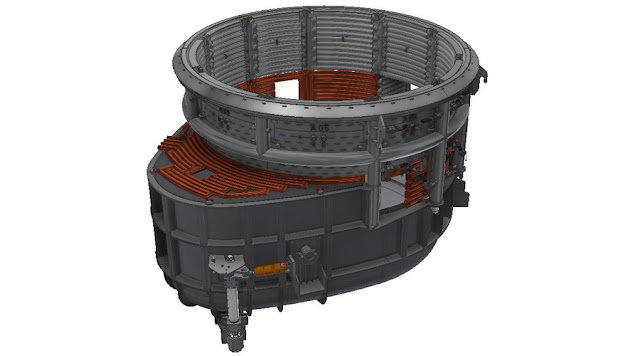

The electric arc furnace process is a key step in steelmaking, where an electric arc is used to melt scrap metal. Traditionally, this process requires manual labor and extensive human intervention. However, with the introduction of automation, the EAF process has undergone a major shift.

Automation of Metallurgical Industry - EAF

Automation of the EAF process involves the use of advanced control systems, sensors and robots to optimize the steelmaking process. These systems provide precise control of temperature, oxygen levels and chemical composition, ensuring consistent and high-quality steel production. By automating tasks such as loading scrap metal, controlling power input and tapping the molten steel, the electric arc furnaces process becomes more efficient and less reliant on human intervention.

One of the main benefits of automating electric arc furnaces processes is increased efficiency. Automation allows for faster and more accurate control of various parameters, thereby reducing process variability and increasing productivity. It also enables continuous monitoring and adjustment, minimizing deviations and optimizing energy consumption. Additionally, automated systems can analyze data in real time, providing valuable insights for process optimization and predictive maintenance.

In addition, automation improves safety in the metallurgical industry. By reducing the need for physical labor in hazardous environments, the risk of accidents and injuries can be minimized. Electric furnace automation systems can handle tasks that require precision and consistency, eliminating human error and ensuring a safer work environment.

Additionally, the integration of advanced sensors can detect potential problems, such as abnormal temperatures or equipment failures, allowing for timely intervention and risk mitigation.

Cost reduction is another significant advantage of electric arc furnace process automation. Automated systems help minimize production costs by optimizing energy consumption and reducing scrap losses. Additionally, automation reduces reliance on skilled labor, which can be costly and prone to human error. Simplification and efficient operation of electric arc furnace processes through automation can lead to higher overall profitability for metallurgical companies.

In summary, automation of metallurgical industry, especially the electric arc furnace process, has revolutionized steel production. By leveraging advanced control systems, sensors and robotics, automation optimizes the steelmaking process to increase efficiency, enhance safety and reduce costs.

As technology continues to advance, further automation will undoubtedly transform the metallurgical industry, driving innovation and making steel production more sustainable.

If you have any questions or needs about IF, EAF, SAF, LF, LRF and other smelting furnaces, please feel free to contact our factory!

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment