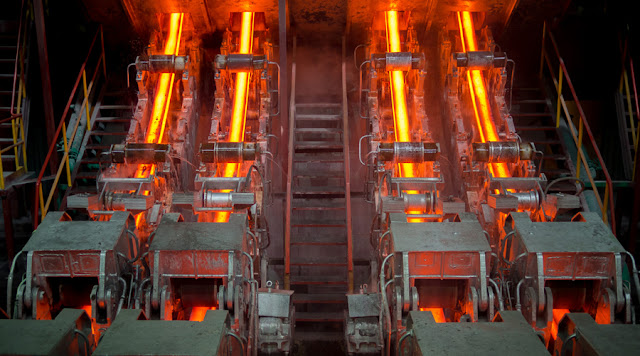

Continuous Casting Machine for Sale

In the process of producing various steel products in steel plants, there are two methods of solidifying molten steel: traditional mold casting and continuous steel casting, and the latter is a continuous casting machine.

Continuous Casting Machine For Sale

Continuous casting (strand casting), also known as continuous steel casting, is the process of solidifying molten metal into "semi-finished" steel billets, blooms or slabs for subsequent rolling in finishing mills.

The process flow of CCM is: molten steel continuously flows into the tundish, is mixed and divided in the tundish, and then injected into the crystallizer for cooling and solidification to obtain an infinitely long cast slab. The cut slab can be directly used for steel rolling production.

Classification

Classification of continuous casting machines for sale

A) Bloom casting machine

B) Vertical continuous caster machine

Structural features: Process equipment such as crystallizer, secondary cooling close-packed clamping section, billet drawing equipment and fixed-length cutting are arranged in the vertical direction.

Scope of Application:

High quality steel or extra large sections. Such as high purity steel, high alloy steel, high S/P steel, etc.; extra thick slab, extra large round billet/square billet.

C) Vertical bending continuous casting machines

There are vertical sections under the crystallizer, which are bent, straightened (the molten steel is completely solidified), and cut horizontally.

* The body height is lower than the vertical type;

* With vertical sections, inclusions are easy to float and evenly distributed;

* Horizontal blanking, the fuselage can be lengthened appropriately, and the fixed length is not limited.

D) Straight arc CCM

* Inclusions are easy to float, which has the advantages of vertical bending continuous casting machine;

*Multiple points of bending reduce stress concentration and reduce cracks;

* It can enter the straightening horizontal section before complete solidification, which can increase the pulling speed and increase the productivity.

Scope of application: slab continuous casting

E) Full arc continuous casting machine

Advantage:

* Body height (1/2~1/3), low infrastructure cost;

* The static pressure of liquid steel is small, and the belly bulge is easy to control;

* High pulling speed and small flow limit.

Scope of application: continuous casting of square billets, round billets, and special-shaped billets

F) Horizontal continuous casting machines

* Low height, low investment;

* No bending straightening, good quality.

G) Ultra-low head continuous caster

Currently, the most widely models of continuous casting machine for sale on the market are full arc continuous casting machines, straight arc continuous casting machines, and vertical continuous casting machines.

HANI Metallurgical's vertical continuous casters are capable of producing extremely special steel grades that meet demanding application requirements. No matter what type of continuous casting machine it is, we will choose and recommend the most suitable one to you.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment