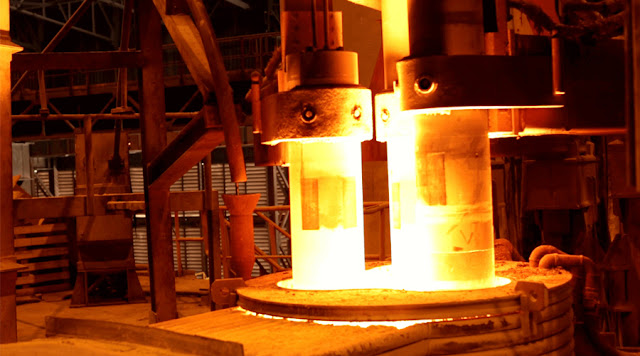

SAF Smelting Furnace

Smelting furnace: revolutionizing metal production

Smelting furnaces are a cutting-edge technology that is revolutionizing the metal production industry. With its advanced design and state-of-the-art features, the furnace is quickly becoming the first choice for companies looking for high-quality, efficient and cost-effective metal melting solutions.

SAF Smelting Furnace Features

a) The heart of the SAF melting furnace is its unique combustion system, which utilizes a combination of oxygen and natural gas to create an extremely hot flame. This flame has a temperature of up to 3000 degrees Celsius, ensuring fast and efficient melting of a variety of metals, including steel, iron, aluminum and copper.

This level of heat can also melt complex alloys and refractory materials, making this furnace suitable for a wide range of applications.

b) One of the outstanding features of submersible furnaces is their excellent energy efficiency. Combustion systems are designed to maximize heat transfer, minimize heat loss and ensure that every unit of energy is used efficiently. This not only reduces energy consumption but also lowers operating costs, making SAF furnaces an economically viable option for businesses of all sizes.

c) In addition to energy efficiency, SAF smelting furnaces also boast excellent productivity. Its advanced control system enables precise temperature regulation, ensuring consistent melting performance.

The furnace also features a large melting chamber capable of holding large volumes of metal, further increasing productivity and reducing downtime.

d) In addition, SAF furnaces employ advanced safety features to protect the operator and the environment. The design includes an innovative gas detection system and automatic shut-off mechanism, ensuring any potential hazard is detected and addressed immediately. This focus on safety not only protects workers but also keeps businesses in compliance with strict industry regulations.

e) Submerged arc furnace smelting furnace are also known for their ease of operation and maintenance. The user-friendly interface and intuitive controls allow operators to easily adjust settings and monitor the melting process. Additionally, the furnace is designed for easy operation, enabling efficient cleaning and maintenance tasks, minimizing downtime and maximizing productivity.

In conclusion, the SAF smelting furnaces is a game changer for the metal production industry. Its advanced combustion system, energy efficiency, productivity, safety features and ease of operation make it ideal for businesses looking to enhance their metal melting processes. With the help of this furnace, companies can achieve higher quality output, reduce costs and increase productivity, thereby gaining a competitive advantage in the market.

If you have any questions or needs about smelting furnace such as submerged arc furnaces, induction furnaces, electric arc furnaces, ladle furnaces, refining furnaces, etc., please feel free to contact our factory.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment