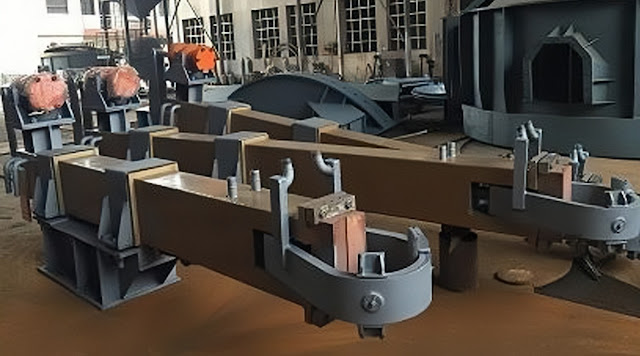

EAF Power Conducting Arms

An important component of an electric arc furnace (EAF) is the conductive cross arm, which plays a vital role in supporting heavy loads and ensuring efficient operation of the furnace.

The EAF power conducting arms are responsible for delivering electrical current to the electrodes, which generate the intense heat needed to melt scrap metal and produce steel.

Features of EAF Power Conducting Arms

The conductive cross arm is made of high-quality conductive materials such as copper or copper alloy, which has excellent conductivity and heat resistance.

These properties are critical to maintaining the stability and reliability of the EAF process.

Electric arc furnace electrode arms must be able to withstand extreme temperatures and high currents, so their material selection becomes a critical factor.

One of the major challenges for conductive cross arms is maintaining their structural integrity under the harsh conditions of electric arc furnaces.

Intense heat and electrical current can cause materials to degrade over time. Therefore, HANI manufacturers use advanced technology to improve the durability and lifespan of conductive cross arms.

To combat the adverse effects of heat and electrical current, manufacturers often use water cooling systems.

These systems circulate water through channels within conductive cross arms, effectively dissipating heat and reducing the risk of damage. In addition, the water cooling system helps maintain a stable temperature, ensuring consistent performance of the conductive cross arms.

Another key aspect of an electric arc furnace EAF power conducting arms is its design.

The cross arms must be carefully designed to accommodate the weight of the electrodes and distribute the current evenly. By correctly distributing the load, conductive cross arms minimize the risk of mechanical failure and ensure a stable operating environment.

Regular maintenance and inspection of conductive cross arms is essential to avoid unplanned downtime and costly repairs.

We usually recommend routine inspections to identify any signs of wear or damage. Prompt identification of problems allows proactive measures to be taken to prevent more serious problems and extend the life of the conductive cross arm.

To sum up, EAF Power Conducting Arms are an important part of the electric arc furnace, responsible for transmitting electric current and supporting the operation of the electric arc furnace. Its durability, heat resistance and electrical conductivity are key factors in ensuring efficient and reliable steel production.

Through careful material selection, water cooling systems, and proper maintenance, manufacturers can maximize the service life and performance of conductive cross arms, thereby contributing to the overall success of the EAF process.

If you have any questions or needs about electric arc furnaces, induction furnaces, submersible furnaces, ladle furnaces and accessories, please feel free to contact us.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment