Key Features of Ladle Refining Furnaces

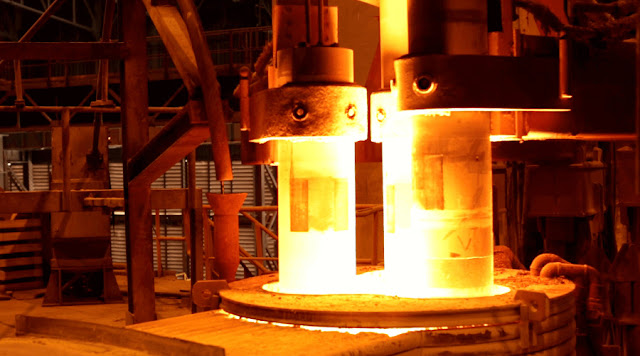

The Ladle Refining Furnaces (LRF) is an important part of the steelmaking process.

They play a vital role in improving the quality of molten steel by removing impurities and adjusting the chemical composition. The LRF has several key features that make it efficient and efficient in steel production.

Characteristics of Ladle Refining Furnaces

a) One of the main features of a ladle refining furnace is the ability to perform multiple refining operations in a single vessel.

The LRF is designed to perform processes such as desulfurization, dephosphorization, deoxidation and temperature regulation in a controlled environment. This eliminates the need for separate operations, saving time and energy.

b) Another important feature of LRF is the precise control of the refining process.

These furnaces are equipped with advanced automation systems that allow operators to monitor and control various parameters such as temperature, oxygen and agitation intensity. This level of control ensures consistent and accurate results, resulting in high quality steel.

c) Ladle refining furnaces are also designed to handle large volumes of molten steel.

They have high capacity and can process tons of steel in one cycle. This makes them suitable for large-scale steel production where efficiency and productivity are critical.

d) In addition, LRF is also equipped with a powerful stirring mechanism to ensure the full mixing of molten steel.

The stirring action helps to achieve uniformity and homogeneity of the steel composition, thereby improving product quality. Stirring is also beneficial to remove non-metallic inclusions that are detrimental to the mechanical properties of the steel.

e) In terms of energy efficiency, ladle furnaces are designed to minimize heat losses.

They are insulated with high-quality refractory materials to help retain heat and reduce energy consumption. In addition, some LRFs are equipped with regenerative burners that recover waste heat and use it to preheat the incoming gas, further improving energy efficiency.

f) Safety features are also an integral part of the ladle refining furnace.

They are equipped with advanced gas analysis systems that continuously monitor the atmosphere inside the furnace. This ensures the presence of required levels of oxygen and prevents the formation of harmful gases. Additionally, the LRF is equipped with an emergency shutdown system to prevent any accidents.

In short, the ladle refining furnaces is an important piece of equipment in the steelmaking industry. Their key features, such as the ability to perform multiple refining operations, precise control, high capacity, powerful mixing mechanisms, energy efficiency and safety features, make them indispensable in the production of high-quality steel.

Continuous advancements in LRF technology and design have further improved its performance, contributing to the growth of the steel industry.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment