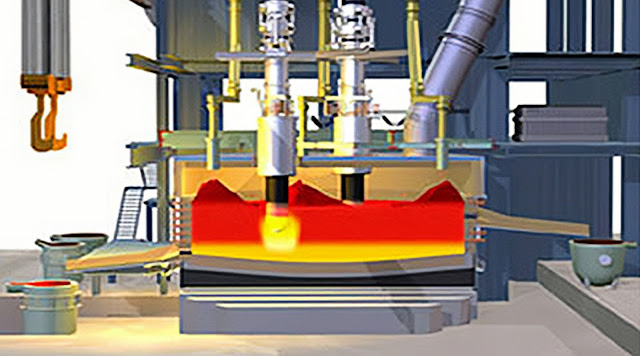

How To Choose Submerged Arc Furnace Transformers?

The submerged arc furnace transformers is an important part of the steelmaking process. These transformers are responsible for converting the high voltage electricity to the low voltage electricity required by the submerged arc furnace. Therefore, choosing the right transformer is crucial to ensure efficient and safe operation of the furnace.

In this article, we will discuss the key factors to consider when selecting a submerged arc furnace transformer.

Submerged Arc Furnace Transformers

1. Rated Power:

The power rating of a transformer determines its ability to handle the furnace's electrical load. It is critical to select a transformer with a power rating that matches the power requirements of the furnace. Power ratings are given in kilovolt-amperes (kVA) and vary according to the size and capacity of the furnace. Consultation with an electrical engineer or transformer manufacturer is recommended to determine exactly the wattage rating required for your particular furnace.

2. Voltage Ratio:

The voltage ratio of a transformer refers to the ratio of the primary voltage to the secondary voltage. For submerged arc furnaces, the primary voltage is usually higher, ranging from 11 kV to 33 kV, while the secondary voltage is much lower, usually around 400 V.

Selecting a transformers with the correct voltage ratio is critical to ensure the efficient transfer of electricity to the furnace. The voltage ratio should be compatible with the electrical system of the facility where the furnace is installed.

3. Cooling Method:

Submerged arc furnace transformers generate a lot of heat during operation.

Therefore, it is critical to choose a transformer with proper cooling methods to prevent overheating and maintain peak performance. There are various cooling methods for transformers, including oil-immersed, air-cooled and water-cooled.

The choice of cooling method depends on the rated power of the transformer, installation environment, maintenance requirements and other factors. It is important to consider the availability of cooling resources and the cost-effectiveness of each cooling method before making a decision.

4. Efficiency:

Transformer efficiency is a key factor to consider as it directly affects the energy consumption and operating costs of the furnace. The efficiency of a transformer depends on its design, construction and materials used.

It is recommended to select a transformer with a high efficiency rating to minimize energy loss and maximize the overall performance of the furnace. Look for transformers that meet international efficiency standards, such as those set by the International Electrotechnical Commission (IEC) or the National Electrical Manufacturers Association (NEMA).

5. Reliability & Durability:

Submerged arc furnace transformers are subject to harsh operating conditions, including high temperatures, heavy electrical loads, and continuous operation.

Therefore, it is crucial to choose a transformer that is reliable and durable enough to withstand these conditions. Look for transformers that are made of high-quality materials, have a solid design, and are manufactured by a reputable company with a proven track record in transformer production.

It is also recommended to consider a transformer with a comprehensive warranty and aftermarket support for long-term reliability and peace of mind.

6. Safety Features:

When choosing a submerged arc furnace transformer, safety should always be the first priority. Look for transformers equipped with various safety features such as overcurrent protection, overvoltage protection, short circuit protection and temperature monitoring systems.

These safety features help prevent accidents, equipment damage and downtime. Also, consider transformers that meet international safety standards, such as those set by the International Electrotechnical Commission (IEC) or the Occupational Safety and Health Administration (OSHA).

7. Maintenance & Service:

Regular maintenance and care is critical to the optimum performance and lifespan of your submerged arc furnace transformer. When selecting a transformer, consider ease of maintenance and availability of spare parts.

It is recommended to choose a transformer with easy access to components and a well-established network of service centers or authorized dealers.

A regular maintenance schedule including inspections, oil analysis and preventive maintenance should be followed to ensure continued reliability and performance of the transformer.

In short, choosing a suitable submerged arc furnace transformers is very important for the efficient and safe operation of the submerged arc furnace. When making your decision, consider factors such as power rating, voltage ratio, cooling method, efficiency, reliability, safety features and maintenance requirements.

Consulting with electrical engineers, transformer manufacturers and industry experts can provide valuable insight and guidance in selecting the best transformer for your specific needs.

Remember, investing in a high-quality transformer will improve furnace performance, reduce energy consumption, and increase productivity in the long run.

You are welcome to pay attention to us, we will continue to share information about metal smelting furnaces such as IF, EAF, SAF, LF, and CCM.

If you have any needs, please feel free to contact us.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment