What Is SAF Electrode?

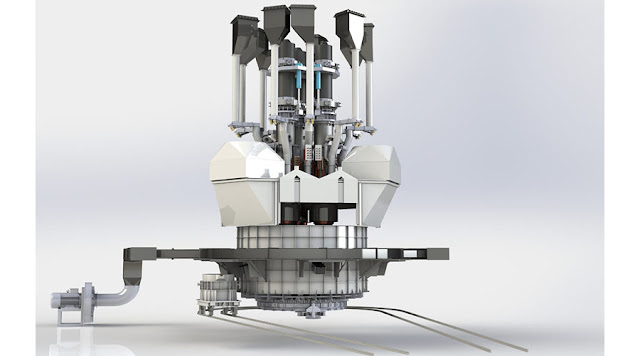

SAF electrode are key components used in submerged arc furnace (SAF) technological processes. A SAF is a furnace that operates by consuming solid raw material and converting it into liquid metal through an electric arc. The electrodes play a vital role in this process by providing the necessary electrical energy to initiate and maintain the arc.

Electrodes used in submerged arc furnaces are usually made of high-quality carbon or graphite materials. It is designed to withstand the extreme heat and chemical environment found in furnaces. The electrodes are usually cylindrical and are connected to a power source by a bracket.

During the working process, the electrodes are gradually consumed by the arc and need to be replaced regularly. Consumption rates depend on factors such as amperage, arc length and the type of raw material being processed. Efficient electrode consumption is critical to maintaining stable operation and minimizing downtime.

SAF electrode are responsible for creating and maintaining the arc, which generates the heat needed to melt the raw material. An arc is formed between the electrode tip and the charge in the furnace. The high temperatures generated by the arc facilitate the chemical reactions necessary for the production of the desired metal.

To ensure optimum performance, the electrodes must be properly positioned in the furnace. It should be placed at an appropriate distance from the charge to maintain the desired arc length. The electrode holder allows for easy adjustment and control of the electrode position.

In addition to providing electrical energy, the SAF electrode also act as conductors of electric current. It must have low electrical resistance and high thermal conductivity to efficiently transfer the energy generated by the power source to the arc.

The choice of electrode material is critical to achieving efficient and reliable furnace operation. Carbon and graphite electrodes are preferred due to their high melting point, good electrical conductivity and resistance to chemical reactions. The choice of electrode material depends on the specific requirements of the furnace and the type of metal being produced.

In conclusion, submerged arc furnace electrodes are an important part of SAF technology. It provides electrical energy, creates and maintains an arc, and acts as a conductor of electrical current. Selection of electrode material and proper positioning are critical to efficient and reliable furnace operation.

You are welcome to pay attention to us, we will continue to share information about metal smelting furnaces such as IF, EAF, SAF, LF, and CCM.

If you have any needs, please feel free to contact us.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment