Electric Induction Furnace Manufacturer - Xi'an Hani Tech

Electric Induction Furnace Manufacturer Xi'an Hani Tech

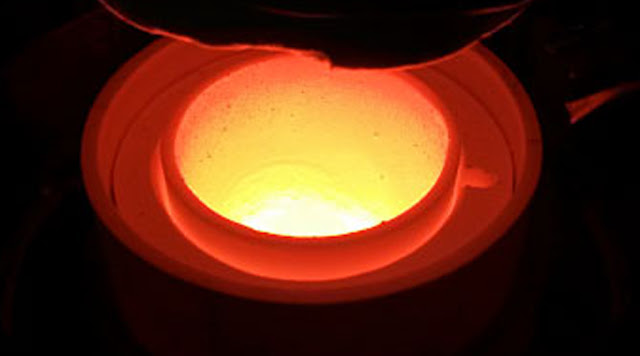

The heating method of the induction furnaces is a little different from other furnaces.

Although it is also driven by electricity, it uses induction heating to heat the material.

It is also a equipment that is in great demand in the smelting industry, so choosing a reliable and guaranteed company among the endless electric induction furnace manufacturer will save costs and guarantee the productivity and after-sales of the equipment.

Before that, we need to understand what an induction furnaces is. Today Hani Metallurgy will take you to understand.

The working principle of the induction furnace:

1. Induction heat treatment furnaces such as induction furnaces have obvious advantages in terms of energy consumption and environmental protection in the production process.

Suppliers have fully considered these issues at the beginning of induction furnace design. These ingenious designs make the induction furnace highly environmentally friendly and energy-saving.

2. Induction heating equipment can effectively reduce heat loss during work, and will not cause high temperature environment in the production workshop.

The durability of the equipment itself has also been greatly improved, with a longer service life than older equipment. Therefore, it is becoming more and more popular in the market.

3. Induction furnace is a kind of equipment that uses the principle of electromagnetic induction for production and heating.

Because induction furnaces are widely used, they can be used as pipes of various sizes.

Induction furnaces are non-standard customized products, requiring users to provide parameters such as workpiece size, process requirements and output, so that induction heating equipment manufacturers can better customize design and production for users. .

Application

Since induction heating is done through a magnetic field, the workpiece can be physically isolated from the induction coil by a refractory material or some other non-conductive medium, and the magnetic field will pass through this material, which means that the workpiece can be heated in a vacuum environment, which enables heating of special alloys, silicon, graphite and other sensitive conductive materials.

Electric induction furnace is currently the most widely used heating equipment in the heating industry. It is not only used in forging industry, casting industry, hot stamping industry, but also widely used in quenching, tempering and other metal quenching and tempering of heat treatment.

If you have any needs or questions about induction furnaces, electric arc furnaces, submerged arc furnaces, ladle furnaces and other metal smelting equipment, please feel free to contact us. As an electric induction furnace manufacturer, we, Xi'an Hani Tech / Hani Metallurgy, will provide you with professional solutions and the best service.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com (Daisy Zhai)

Tel / Whatsapp / Wechat: 0086 17791213533

Xi'an Hani Tech Co., Ltd.

Comments

Post a Comment