Ladle Furnace Transformer Maintenance

Ladle furnace transformer are a must-have product in the electric arc furnace smelting industry, and their quality and maintenance have always been concerned.

The following is an introduction to the maintenance of the ladle furnace transformer.

It is necessary to suspend the core of the ladle furnace transformer after long-distance transportation.

It's necessary to check and replace the mechanical wear parts according to the original overhaul cycle.

Such as pumps and other moving parts, but for a relatively static transformer, it is not necessary to hang the core for a long time, and only monitoring the quality changes such as gas chromatography of the oil is enough to grasp the situation of the body, thereby saving maintenance costs and reducing the impact of the hanging core on the body and oil. Pollution.

Product Quality Assurance Measures

1 Guaranteed long-term overload of 20%.

If the transformer capacity of the ladle furnace is 20000KVA, the design basis capacity of the winding should be set to 24000kVA,

In particular, the current density and switch selection should be selected according to 24000kVA, and the impedance voltage should not be greater than 8% at 24000kVA.

It has good external characteristics and economy. The heat load calculation of the transformer is set at 24000kVA, and when there is a certain margin of 24000kVA, select the load-related accessories such as the lead wire, the secondary outlet, and the cooler.

2. Technical measures for impact resistance and short circuit resistance

Improve the axial and radial stability of the transformer coil, thereby reducing the accumulation of damage to the transformer coil for each impact.

Specific Measure:

1) Choose a magnet wire with a higher voltage level and a tightly wrapped surface-treated magnet wire.

2) After the magnet wire is purchased, it should be dried first, and then wound to prevent the coil insulation paper from being wet, which will affect the winding tightness of the coil.

3) The spacer is used after densification and densification to reduce the axial compression margin of the coil.

4) The struts are dehaired to reduce the friction between the struts and the "dovetail" of the spacer block, so that the force transmission resistance of the coil is small when the coil is pressed axially.

5) Coil drying adopts constant pressure drying.

6) The inner coil adopts multiple support bars, and the outer coil adopts outer stays to ensure that the displacement of the wire cake is small during short-circuit impact.

7) The body is dried in vapor phase.

8) Hydraulic device is used for pressing the body.

3. Guarantee technical measures to avoid overhaul within 20 years of operation.

Hani Metallurgy's main consideration is the stability and reliability of the transformer windings.

The second is to prevent the aging of transformer oil and the aging of seals. Transformer oil, we choose high-quality naphthenic oil,

The anti-aging ability is strong, coupled with the closed structure, the diaphragm oil conservator is equipped with a pressure release valve, so that the oil does not come into contact with the air, so the oil can be used in normal operation within 20 years.

In addition to the anti-aging pad, the main sealing surface of the anti-leakage should be machined so that the pad and the metal are pressurized on three sides, and the contact with the air is reduced.

In addition, users normally do oil chromatographic analysis every 6 months, and store them in the file to distinguish the normal aging of the oil from faulty operation, so as to ensure that the products used are assured.

It is recommended for transformer on-load switches that the oil breakdown voltage in the switch should be changed frequently according to the number of operations, and the value should be in line with the switch. In the design, butterfly washers should be used for all fasteners of the body to prevent loosening to enhance the reliability of loosening. sex.

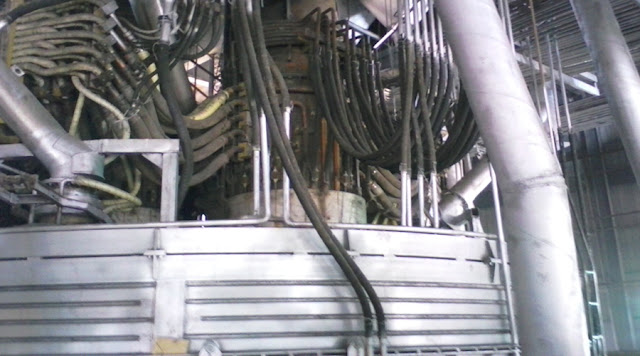

4. Appearance

In the design, the structure of the product is compact, and various transformer control lines are connected to a unified junction box and the purpose is explained, so that the appearance is beautiful and the operation is convenient.

For more information on ladle furnace transformers, welcome to discuss with us.

If you have any needs about electric arc furnace, ladle furnace, melting furnace etc, please feel free to contact us.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com

Whatsapp/Wechat: 0086 17791213533

More Literature: EAF & CCM Machine

Comments

Post a Comment