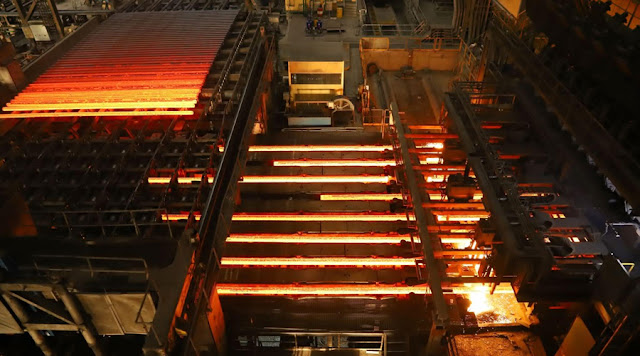

Billet Manufacturing - Steelmaking

Billet manufacturing refers to the process of rolling steel ingots into slabs, billets & special-shaped billets on a blooming mill, and destroying the casting structure of the steel ingot, which is called blooming.

A billet is a product obtained by casting molten steel made in a steelmaking furnace.

Steel billets can be mainly divided into two types in terms of manufacturing process: die casting billets and continuous casting billets (the die casting process has been basically eliminated)

Steel billet manufacturing is a new process and technology that has emerged on the basis of the development of continuous steel casting technology in recent years.

It's that after the continuous casting billet comes out of the continuous casting machine, while it is still in a hot and high temperature state, it is rolled into a billet or directly rolled into a finished steel without reheating or a little compensation heating.

In terms of shape, billet manufacturing is mainly divided into two types:

Slab: The ratio of section width and height is large, and it is mainly used for rolling plates.

Billet: The width and height of the section are equal, or the difference is not large, and it is mainly used for rolling section steel and wire rod.

Use:

The billet is originally steel.

After the billet is manufactured and processed, it can be used as mechanical parts, forgings, processing various steels, section steel Q345B channel steel, and wire rod is the role of the billet.

Material:

In the billet manufacturing, continuous cast steel billets and rectangular billets are mainly represented by ordinary carbon steel, low-carbon and low-silicon cold-rolled materials, high-quality carbon structural steel, low-alloy high-strength steel, and special steel grades.

Production Process:

Billet fabrication is produced by three process methods:

First

Through the continuous casting equipment of the steelmaking system, the molten steel is directly cast into the billet;

Second

The semi-finished steel products processed by the rolling equipment of the steel rolling system for the steel ingots or continuous casting billets produced by the steelmaking system;

Third

The semi-finished product processed by the forging equipment for the ingot produced by the steelmaking system.

Hani Metallurgy's customers usually demand more bloom, billet, vertical, vertical bending, slab type continuous casters.

Continuous casting machines with different requirements can continuously cast the required billets to meet the requirements of use.

You are welcome to add more information about billet manufacturing or have any needs, please feel free to contact us.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com

Xi'an Hani Tech Co.,Ltd.

Comments

Post a Comment