Hani Metallurgy Continuous Casting Machine Sale

What is Continuous Casting Machine:

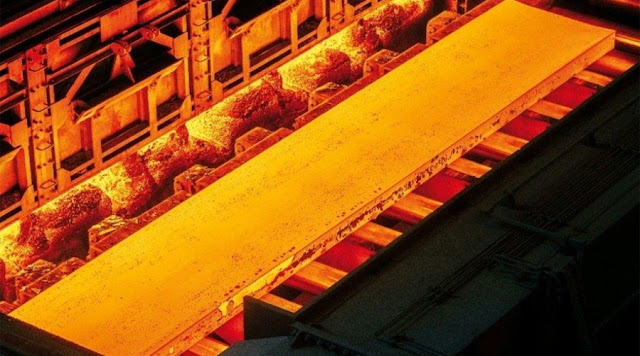

Continuous casting machine is a large metallurgical equipment.

It mainly consists of ladle turntable, steel pouring car, tundish, mold, secondary cooling device, dummy and its hoisting device, billet drawing and straightening device, billet (raceway) device, cutting device, turning cooling bed, etc. The equipment is composed of continuous casting of liquid molten steel into continuous casting billets, which are then cut to the required length by the cutting system.

That is, the molten steel at a high temperature of more than 1500 degrees Celsius can be poured into the intermediate tank lined with refractory materials above the crystallizer,

After cooling through a crystallizer (the inner wall of which can be cooled by water to protect itself), and after the outlet of the crystallizer,

A complete set of mechanical equipment for continuous casting of steel billets by clamping and pulling the end of the steel cooled into a solid state.

Hani Metallurgy continuous casting machine sale according to customers' project needs.

Features:

The purpose of continuous casting: to cast molten steel into billets.

The ladle containing the refined molten steel is transported to the turntable. After the turntable is rotated to the pouring position, the molten steel is poured into the tundish.

The tundish then distributes the molten steel to each mold from the nozzle.

The mold is one of the core equipment of the continuous casting machine, which forms the casting and rapidly solidifies and crystallizes.

The tension leveler and the crystallizing vibration device work together to pull out the castings in the mold, and after cooling and electromagnetic stirring, they are cut into slabs of a certain length.

Continuous Casting Machine Type:

Structure:

Vertical Continuous Caster

Vertical bending caster,

Arc continuous casting machine with straight section,

Arc continuous casting machine

Multi-radius oval caster

Horizontal caster.

Thin slab caster

The Size & Shape of The Cast Section

Slab caster,

Billet caster,

Bloom casting machine,

Round billet caster,

Special-shaped section continuous casting machine

Thin slab caster.

Billet Flow

The number of strands that can be cast under a common ladle is divided into

Single-strand, dual-strand or multi-strand casting.

Therefore, the continuous casting machine sale need to make specific plans and quotations according to the customer's specific projects, structures, sections, and flow requirements.

You are welcome to contact us at any time for consultation!

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com ( Daisy Zhai )

Xian Hani Tech Co.,Ltd.

Comments

Post a Comment