Continuous Casting Machine Process

What is the continuous casting machine process?

The continuous casting process is a production process in the foundry industry.

After the molten steel produced by the converter is refined in the refining furnace, the molten steel needs to be cast into billets of different types and specifications.

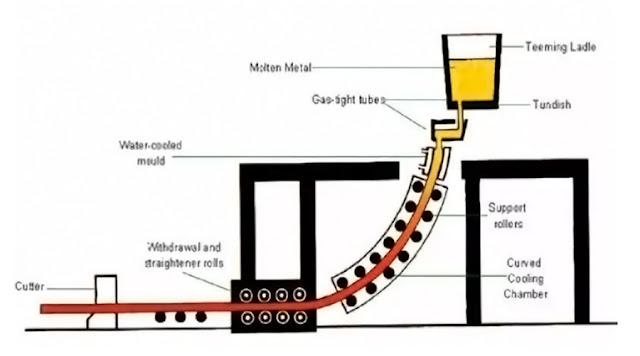

The continuous casting process is the production process of continuously casting the refined molten steel into billets. The main equipment includes a rotary table, a tundish, a mold, and a tension leveler.

So what is the process of the continuous casting machine process?

Hani Metallurgy explains it for you as follows:

Continuous casting is an intermediate link connecting steelmaking and rolling, and is an important part of a steelmaking plant (or workshop).

The technological process of continuous casting production is:

Ladle → tundish → mold → secondary cooling → billet straightening → cutting → roller conveying → pusher → casting billet.

Transport the ladle containing the refined molten steel to the turntable →

After the turntable rotates to the pouring position, pour the molten steel into the tundish →

The tundish distributes the molten steel to each mold from the nozzle →

The mold is one of the core equipment of the continuous casting machine, which makes the casting shape and rapidly solidifies and crystallizes →

The tension leveler and the crystallizing vibration device work together to pull out the castings in the mold, and after cooling and electromagnetic stirring, they are cut into slabs of a certain length.

The application of continuous casting technology has completely changed the production process and logistics control of the steelmaking workshop.

It provides conditions for the continuous production of workshops, the application of automation and information technology, as well as greatly improving the environment and improving product quality.

In addition, the development of continuous casting technology will also drive the development of other industries in the metallurgical system.

It plays an important role in promoting the simplification and optimization of enterprise organizational structure and product structure.

Hani Metallurgy specializes in continuous casting machines for the production of various types, streams, blooms, billets, and other smelting equipment.

Any needs, please feel free to contact us, we will give you the best solution as soon as possible.

E-mail: saleswn@hanrm.com / inquiry66@hanmetallurgy.com ( Daisy )

Comments

Post a Comment