What are the characteristics of electric arc furnace steelmaking?

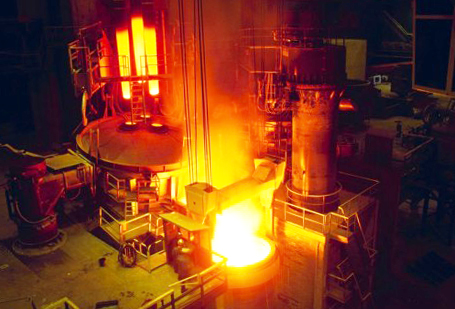

Electric arc furnace (EAF for short) steelmaking is a steelmaking method that uses electric energy as a heat source. It relies on the electric arc generated by the discharge between the electrode and the charge to convert the electric energy into heat in the arc and uses the arc radiation and the direct heating effect of the electric arc. A steelmaking method that heats and melts metal charge and slag to smelt various qualified steels and alloys.

So what are the characteristics of electric arc furnace steelmaking:

(1) Electricity is the heat source to avoid the pollution of molten steel by burning fuel, and the thermal efficiency is high, reaching more than 65%;

(2) The temperature of the smelting bath is high and easy to control, meeting the requirements of smelting different steel grades;

(3) Electric heating conversion, the power input to the molten pool is easy to adjust, so it is easy to realize the automation of the molten pool heating system, and the operation is convenient;

(4) Electric arc furnace steelmaking can dissipate steel scrap, it is a process of iron resource recycling and reuse, and it is also an environmentally friendly technology to deal with pollution. It is equivalent to a recycling tool for scrap steel in the steel industry and society.

(Due to the good renewability of steel and the increasingly stringent requirements of the environment, resources, and energy, it has become an international trend to use scrap steel as much as possible. If scrap steel is not effectively recycled and used, it will become a huge

Some potential environmental pollution sources may even pose a serious threat to water quality and soil. A large amount of rusty steel waste will not only cause waste of resources but also cause serious dust pollution. The accumulation of scrap steel itself also has an adverse effect on the environment. )

(5) The flue gas pollution and noise pollution in the steelmaking process are easy to control;

(6) The equipment is simple, the steelmaking process is short, the area is small, the investment is low, the plant is built quickly, and the production is flexible.

If the large number of solid steel products produced by the iron and steel industry is not taken seriously, they will be a huge source of potential environmental pollution, and some of them may even pose a serious threat to water quality and soil. Today's steel production can be divided into two major processes: "from ore to steel" and "from scrap to steel". Compared with the conventional process represented by blast furnace-to-converter steelmaking in the steel complex, the electric arc furnace steelmaking production line with scrap steel as the main raw material has the characteristics of fewer processes, low investment, and short construction period, so it is called a short process.

In recent years, the short process refers specifically to those compact production processes that combine electric arc furnace steelmaking with continuous casting and continuous rolling. It can be seen that in terms of investment, efficiency, and environmental protection, the short process steelmaking represented by the electric arc furnace has obvious advantages.

If you have any thoughts and suggestions, welcome additional exchanges. I will feel very honored!

E-mail: saleswn@hanrm.com

Daisy Zhai

Comments

Post a Comment